Many years of experience, certified skills and continuous technological investment: these are the elements that over the years have made Anoxidall the leading company in the anodic oxidation process, also called anodization.

It is an irreversible electrochemical process, which consists in the formation of an indelible, thin protective layer of aluminum oxide on the surface of the treated metal, transparent and extremely porous, with the aim of improving the surface characteristics of the material under various aspects, in particular:

In addition to the classic silver colour, typical of natural aluminum, Anoxidall is able to offer the customer various types of colours and finishes.

Chimico ARC

Brushing Tinex

Brushing Scotch Brite

Polished

Shot Blasting

Anoxidall has been operating in the anodic oxidation sector since 1967, the year in which its founder, Umberto Re, opened the first anodizing plant in the whole of Friuli Venezia Giulia.

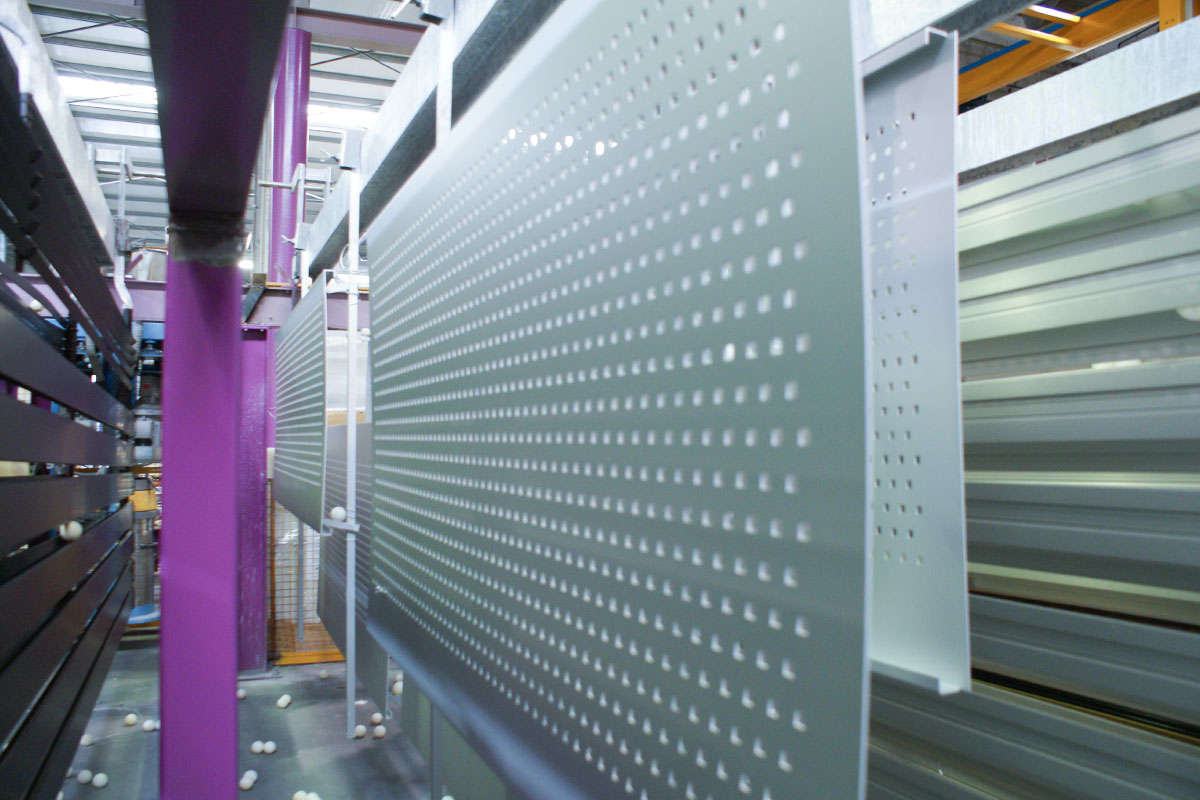

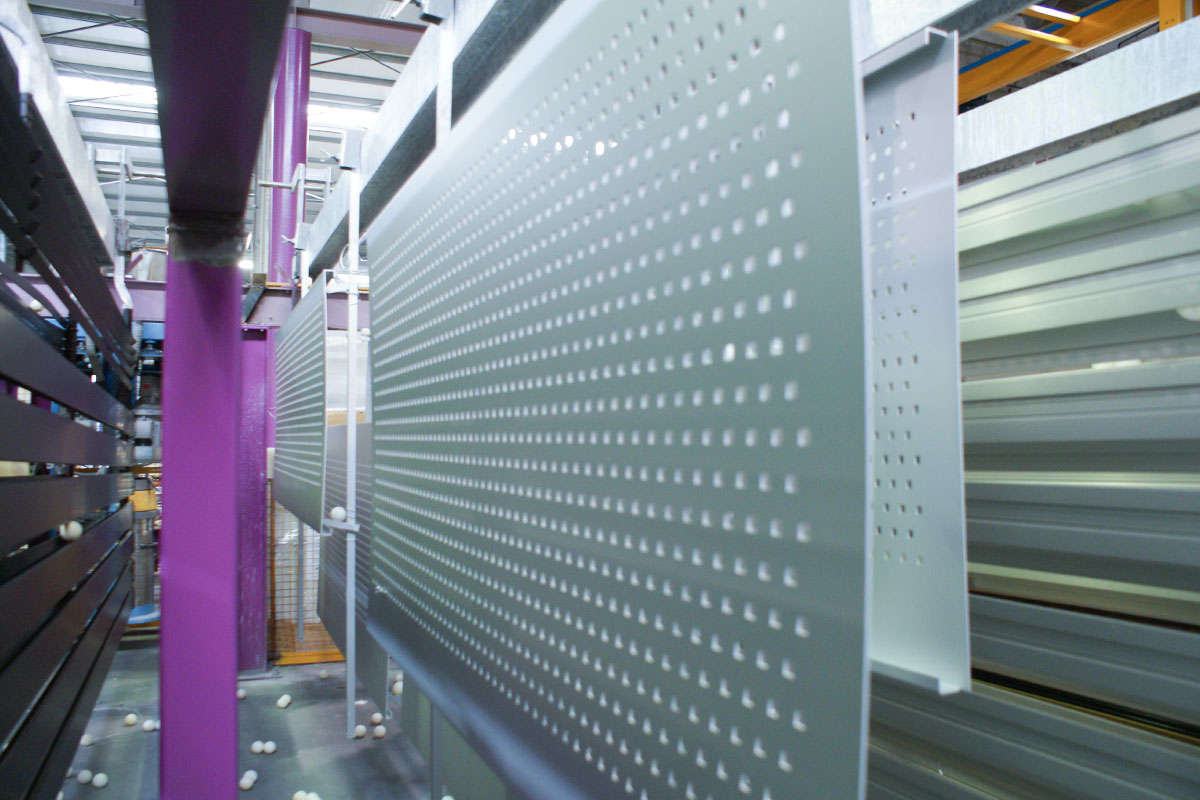

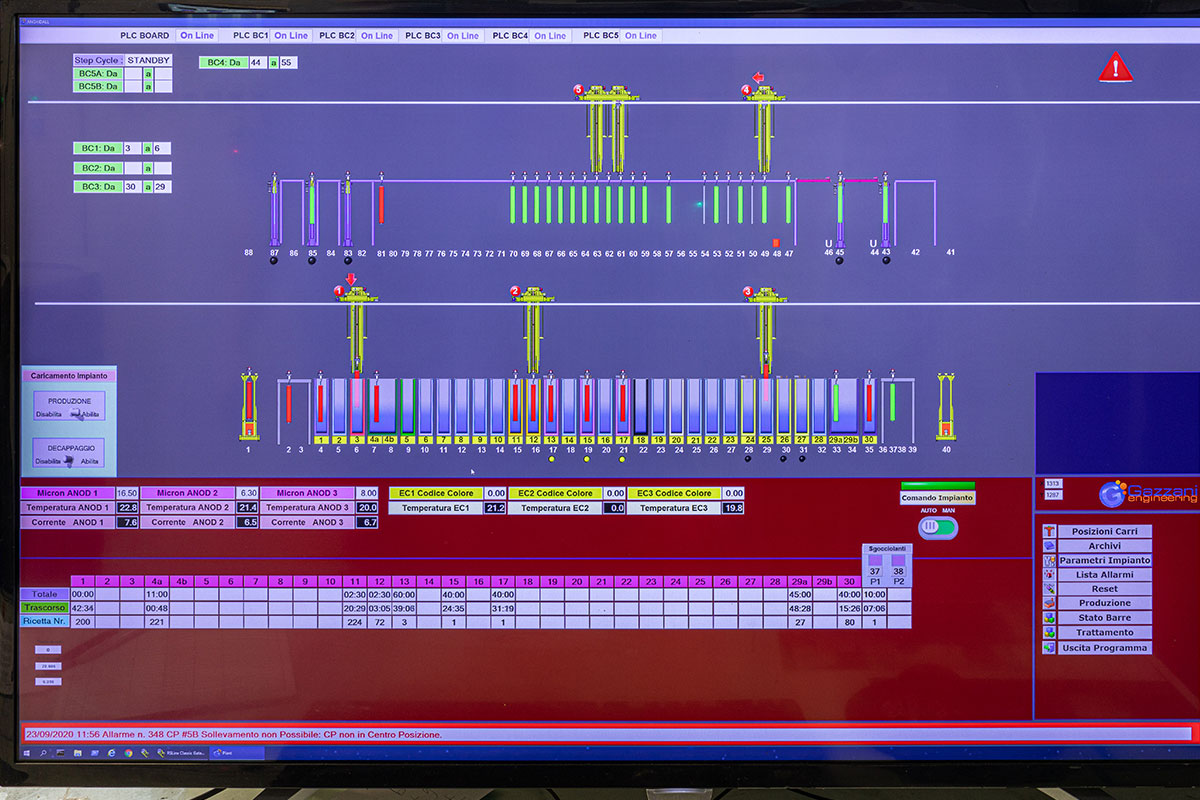

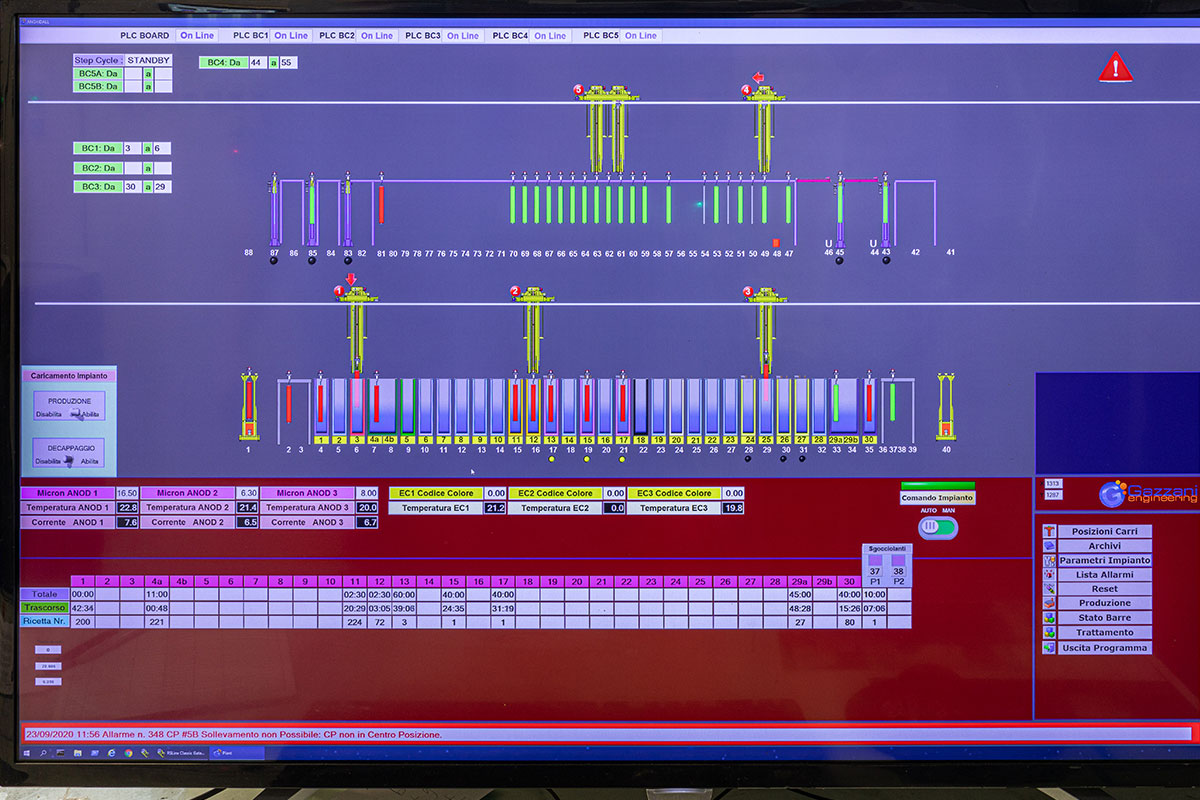

Since then, the continuous investment in research and development of this process has led to the adoption of an industry 4.0 philosophy with the implementation of the current anodic oxidation plant, a state-of-the-art facility, fully automated and environmently friendly, where all the physico-chemical parameters of the acid or alkaline baths are automatically monitored.

Anoxidall is certified with the Qualanod brand: all the production and anodic oxidation processes of aluminum take place in full compliance with national and international standards, to guarantee customers only high and constant quality standards over time.

The anodic oxidation process of aluminum begins with a series of advanced pre-treatments necessary to make the product suitable for the subsequent phases, such as degreasing, satin finishing and acid neutralization, with which to eliminate insoluble hydroxides due to previous treatments.

Subsequently, the actual anodizing takes place: the aluminum product is immersed in an electrolysis bath, or in a tank of acid solution with the passage of an electric current through connection to an anode.

Anodic oxidation has assumed great importance over the years, becoming today one of the most widespread and effective techniques for the protection of light metals. From construction to aeronautics, from electronics to mechanics, from lighting to purely decorative applications: thanks to its exceptional aesthetic and conservation properties, oxidized aluminum is used both in the construction of internal structures that do not require frequent manipulation, as well as for structures exposed to the urban, industrial or marine atmosphere.

The thickness of the protective layer varies according to individual customer requests and the use for which the material is intended. Obviously, the thicker the layer, the better the weather resistance.

THICKNESSES FOR INTERNAL

| Class 5 | thickness µm 5 |

| Class 10 | thickness µm 10 |

THICKNESSES FOR INTERNAL EXTERNAL APPLICATIONS

| Class 15 | thickness µm 15 |

| Class 20 | thickness µm 20 |

| Class 25 | thickness µm 25 |